Time: 13 November 2023 | Source: Acrel

Abstract: With the promotion of smart substations, the power system adopts reliable, integrated, and environmentally friendly smart equipment, relying on the digitization of station-wide information, standardization of information sharing, and networking of communication platforms to automatically complete the collection, measurement, protection, and monitoring of substation equipment information. For basic functions such as control, the traditional "visible" and "tangible" secondary circuit has become an "invisible" and "tangible" "black box", which increases the uncontrollability of substation operation, maintenance and maintenance. , this paper proposes a research plan for an intelligent substation operation and maintenance management platform. It can remotely control and control the substation relay protection. Enable remote online monitoring and intelligent operation and maintenance management of operation and maintenance stations and maintenance work areas.

Keywords: online monitoring, condition assessment, fault location, auxiliary safety measures, fault analysis

0.Introduction

To improve the maintenance level of substation secondary equipment, it is necessary to visualize the equipment, provide multi-dimensional visual information support, decision-making and safe operation for the daily operation and maintenance, abnormality handling, accident analysis and maintenance of substation secondary system, and develop advanced applications based on the operation and maintenance platform to improve the level of equipment refinement management.

The substation intelligent operation and maintenance management platform obtains information from the process layer network and station control layer network, highly integrates the information related to operation and maintenance, realizes the applications of visualized online monitoring and intelligent diagnosis, and supports remote uploading. Its main functions include multi-dimensional operation and maintenance management, such as online monitoring, condition assessment and monitoring and warning of secondary equipment, fault localization, auxiliary safety measures for secondary maintenance, configuration file management, protection value management, fault information management and comprehensive analysis.

1.Overview of substation operation and maintenance cloud platform

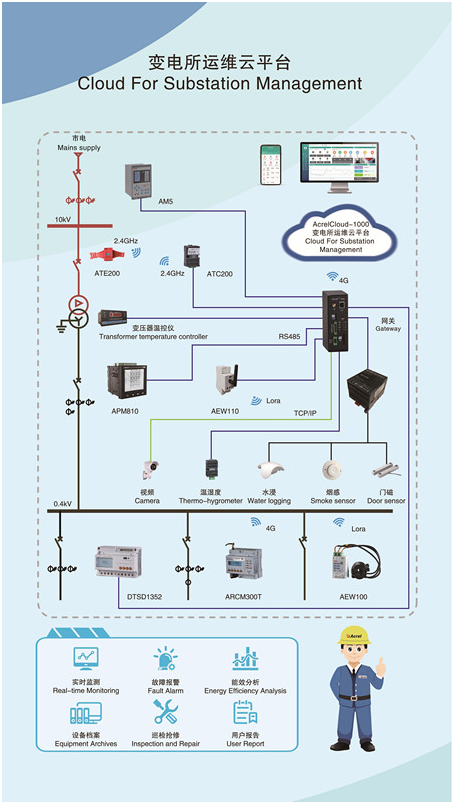

AcrelCloud-1000 substation operation and maintenance cloud platform based on Internet +, big data, mobile communications and other technology development of the cloud management platform, to meet the needs of users or operation and maintenance companies to monitor the operating status and parameters of many substation circuits, indoor environmental temperature and humidity, cable and busbar operating temperature, on-site equipment or environmental video scenes, etc., to achieve a center of the data, centralized storage, unified management, easy to use, to support the user with the right to access through the computer, cell phone, PAD and other types of terminal links, receive alarms, and to complete the relevant equipment, such as daily and regular inspections and dispatches, etc., management.

2.Application

It is applicable to the new construction, expansion and reconstruction of power distribution operation and maintenance system in telecommunication, finance, transportation, energy, medical and health care, culture and sports, education and scientific research, agriculture, forestry and water conservancy, commercial services, public utilities, electronic industrial park and other industries.

3.platform structure

A set of intelligent gateway is installed in the substation distribution room to collect the data of intelligent equipment in the substation room, and after protocol conversion, compression and encryption, it is uploaded at regular intervals or uploaded to the platform in a triggered manner. The platform can complete the data exchange of all the intelligent equipments in the substation and distribution room, and it can real-time monitor the operation status of transformers, circuit breakers, and other important operating equipments in the substation; it can real-time monitor the operation data of the circuits in the substation and distribution room as well as the digital quantities of the ambient temperatures etc.; and the communication and management unit is connected with the plant's local area network (LAN) and passes the data to the data center.

AcrelCloud-1000 substation operation and maintenance cloud platform provides user profiles, power data monitoring, power quality analysis, power consumption analysis, daily, monthly and annual energy consumption data reports, abnormal event alarms and records, operating environment monitoring, equipment maintenance, user reports, Operation and maintenance dispatching and other functions, and supports multi-platform and multi-terminal data access.

The AcrelCloud-1000 substation operation and maintenance cloud platform system can be divided into four layers: perception layer, transmission layer, application layer and display layer.

Perception layer: includes multi-functional instruments, temperature and humidity monitoring devices, cameras, switching quantity acquisition devices, etc. installed in the substation. In addition to the camera, other devices are connected to the RS485 port of the on-site smart gateway through the RS485 bus.

Transport layer: includes on-site intelligent gateways, switches and other equipment. The intelligent gateway actively collects data from on-site device layer devices, performs protocol conversion, data storage, and uploads the data to the designated server port through the switch. When the network fails, the data can be stored locally and resumed from the interrupted location when the network recovers. Upload data to ensure that server-side data is not lost.

Application layer: includes application server and database server. If the number of substations is less than 30, the application server and database server can be configured in one. The server needs to have a fixed IP address to receive data actively sent by each smart gateway.

Display layer: Users access platform information through multiple terminals such as mobile phones, tablets, computers, etc.

4.platform functions

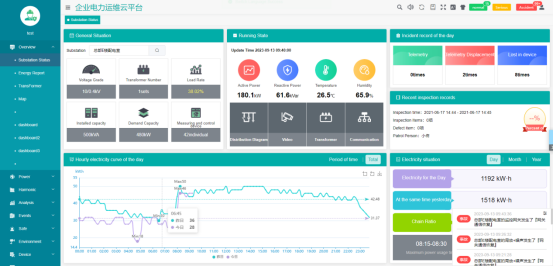

4.1. Real-time monitoring

Click on the power distribution circuit to view detailed power consumption data, generate power operation reports, and query historical data and environmental data monitoring of various power parameters, voltage, current, power, harmonics, etc.

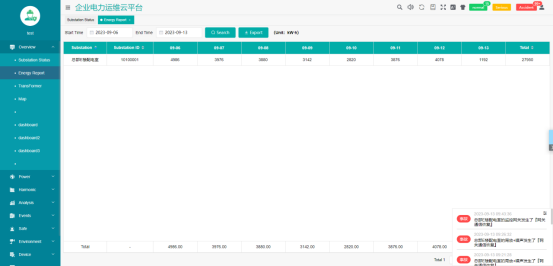

4.2. Monthly energy consumption report

The monthly energy consumption report allows users to query the electricity consumption of managed stations based on total electricity consumption, substation name, substation number, etc. The query span can be set to months.

4.3. Site monitoring

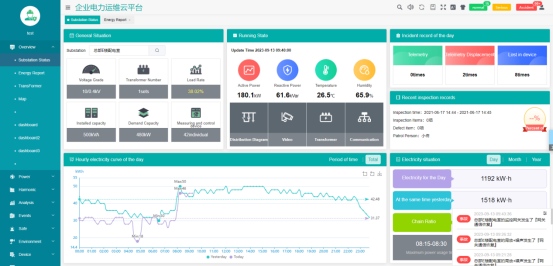

Site monitoring includes overview, operating status, event records of the day, hourly power consumption curve of the day, and power consumption overview.

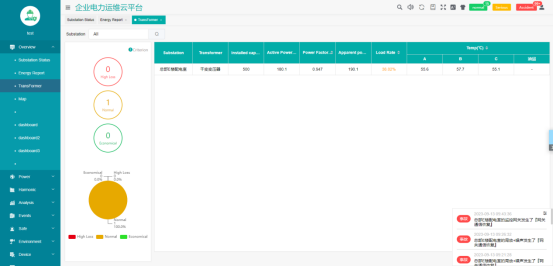

4.4. Transformer status

Transformer status supports users to query the transformer power, load factor, and other operating status data of all or a certain station, and supports ranking in ascending or descending order by load factor, power.

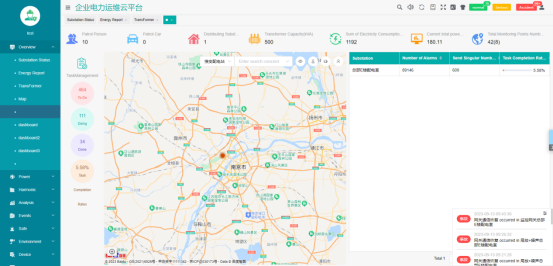

4.5. Power operation and maintenance

Operation and maintenance displays the location and total amount information on the substation map currently managed by the user.

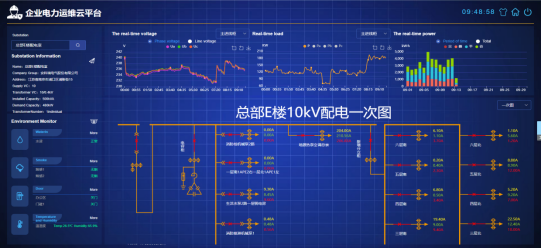

4.6.Power distribution diagram

The power distribution diagram displays the power distribution information of the selected substation. The power distribution diagram displays the switching status, current and other operating status and information of each circuit, and supports detailed operating parameter queries such as voltage, current, and power.

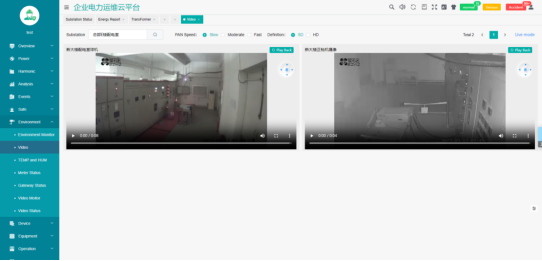

4.7.Video surveillance

Video surveillance displays the current real-time picture (video live broadcast). By selecting a certain power transformation and distribution station, you can view the video information in the power

transformation and distribution station.

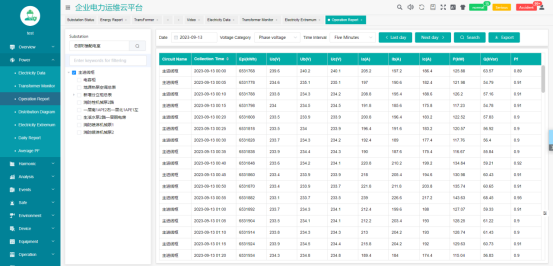

4.8. Power operation report

The power operation report displays the real-time values and average row statistics of the specified collection interval operating parameters of each circuit of the selected equipment in the selected station and the electric energy meter reading.

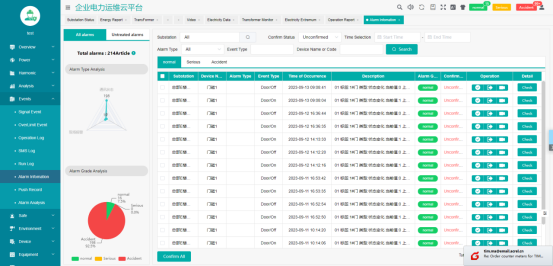

4.9. Fault alarm

Telemetry, remote signaling alarm (webpage and SMS), upper and lower alarm limits can be set, alarm for substation operating environment (flooding, smoke, etc.)

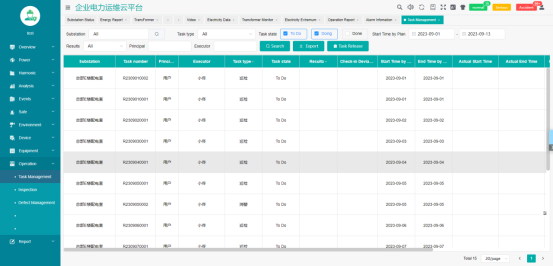

4.10. Task management

The task management page can publish inspection or defect elimination tasks, check the status and completion of inspection or defect elimination tasks, and click View Task to view specific inspection in information

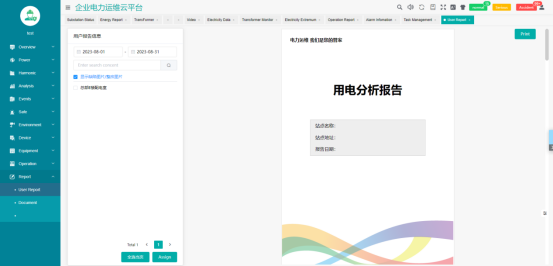

4.11. User Report

The user report page is mainly used to automatically summarize a month's operation data of the selected transformer and distribution station, perform statistical analysis on transformer load, distribution circuit power consumption, power factor, alarm events, etc., and list them within that period. Various types of defects discovered during inspections and their treatment.

4.12. Mobile APP

The APP supports power operation and maintenance. The mobile APP supports seven modules: "monitoring system", "equipment files", "to-do items", "inspection records", "defect records", "document management" and "user reports". Primary graph, demand, electricity consumption, video, curve, temperature and humidity, year-on-year, month-on-month, power quality, various event alarm inquiries, equipment file inquiries, to-do event processing, inspection record inquiries, user reports, document management, etc. .

5.System hardware configuration

|

Application |

Model |

Image |

Function |

|

Substation operation and maintenance cloud platform |

AcrelCoud-1000 |

|

The platform provides user profiles,power data monitoring, power quality analysis,power consumption analysis,daily, monthly and annual energy consumption data reports,abnormal event alarms and records, operating environment monitoring, equipment maintenance,user reports,operation and maintenance dispatch and other functions,and supports Multi-platform, multi-terminal data access |

|

Gateway |

ANet-2E4SM |

|

4 RS485 serial ports,optocoupler isolation,2 Ethernet interfaces, supporting ModbusRtu,ModbusTCP, DL/T645-1997,DL/T645-2007, CJT188-2004,OPC UA,ModbusTCR(master,slave),104 (master-slave),building energy consumption,SNMP,MQTT;(main module) input power supply: DC 12V~36V.Supports 4G expansion module,485 expansion module. |

|

Extension modules ANet-485 |

M485 module:4-channel optocoupler isolation RS485 |

||

|

Extension modules ANet-M4G |

M4G module:supports 4G full network communication |

||

|

Medium voltage incoming line |

AM6-L |

|

Three-stage overcurrent protection (with direction,low voltage locking),overload protection,PT disconnection alarm,reverse power protection, three-phase one-time reclosing, low-frequency load shedding, synchronization detection, loop closing protection,circuit breaker failure protection |

|

Medium voltage incoming line |

APM810 |

|

Three-phase(I,U,kw,kvar,kwh, kvarh,Hz,cosΦ),zero-sequence current In; four-quadrant electric energy,real-time and demand, current and voltage imbalance load current histogram display;66 alarm types and external events (SOE),16 event records each,supporting SD card expansion recording;2-63 harmonics; 2DI+2D0,RS485/Modbus; LCD display; |

|

APView500 |

|

Phase voltage and current + zero-sequence voltage and zero-sequence current,voltage and current unbalance,active and reactive power and energy,event alarm and fault recording, harmonics(voltage/current 63 harmonics,63 inter-group harmonics,harmonics Phase angle, harmonic content rate,harmonic power,harmonic distortion rate, K factor),fluctuation/flicker, voltage swell,voltage sag,voltage transient,voltage interruption, 1024-point waveform sampling,triggering and timing recording Wave, waveform real-time display and fault waveform viewing,PODIF format file storage,memory 32G,16D0+22D1, communication 2RS485+1RS232+1GPS, 3 Ethernet interfaces (+1 maintenance network port) + 1USB interface,supports U disk reading data ,supports 61850 protocol. |

|

|

Medium voltage feeder

Medium voltage feeder |

AM6-L |

|

Three-stage overcurrent protection (with direction, low voltage locking), overload protection, PT disconnection alarm, reverse power protection, three-phase one-time reclosing, low-frequency load shedding, synchronization detection,loop closing protection,circuit breaker failure protection |

|

APM810 |

|

Three-phase (I,U,kw,kvar,kwh, kvarh,Hz,cosΦ) zero sequence current In;four-quadrant electric energy;real-time and demand, current and voltage imbalance;load current histogram display;66 alarm types and external events (SOE), 16 event records each,supporting SD card expansion record;2-63rd harmonic;2DI+2D0 RS485/Modbus;LCD display |

|

|

Medium voltage feeder |

AEM96 |

|

Three-phase electrical parameters U,I,P,Q,S,PF,F measurement,total forward and reverse active energy statistics,forward and reverse reactive energy statistics;2-31 sub-harmonic and total harmonic content analysis, Phase-separated harmonics and fundamental wave electrical parameters(voltage,current, power);current specification 3X1.5(6)A, active energy accuracy 0.5S level,reactive energy accuracy level 2;operating temperature:-10C~+55C;Relative humidity:≤95,no condensation |

|

Low voltage outlet |

AEM72 |

|

Three-phase electrical parameters U,I,P,Q,S,PF,F measurement,total forward and reverse active energy statistics,forward and reverse reactive energy statistics;2-31 sub-harmonic and total harmonic content analysis,Low-voltage outlet line split-phase harmonics and fundamental wave electrical parameters(voltage,current, power);current specification 3x1.5(6)A,active energy accuracy 0.5S level,reactive energy accuracy level 2 |

|

Low voltage outlet |

ADW300 |

|

Three-phase electrical parameters U,I,P,Q,S,PF,F measurement, active energy measurement (forward and reverse),four-quadrant reactive energy,total harmonic content,fractional harmonic content(2nd to 31st);A, B, C, N four-channel temperature measurement,1 channel residual current measurement;supports RS485/LoRa/2G/4G/NB;LCD display; active energy accuracy:0.5S level (recommended for renovation projects) |

|

Wireless temperature measurement |

ATE400 |

|

Fixed with alloy sheet,CT induction takes power,starting current is greater than 5A, temperature measurement range -50~125℃,measurement accuracy ±1℃;transmission distance is 150 meters in open space |

|

ATC600 |

|

Two working modes:terminal and relay.ATC600-Z does relay transparent transmission.The transmission distance from ATC600-Z to ATC600-C is 1000m. ATC600-C can receive data transmitted by ATE series sensors, AHE,etc.,1 channel 485,2 alarm outlets |

|

|

Ambient temperature and humidity |

WHD |

|

WHD temperature and humidity controller products are mainly used for internal temperature and humidity regulation and control of medium and high-voltage switch cabinets, terminal box ring network cabinets, box-type transformers and other equipment. Working power supply AC/DC85~265V, working temperature: -40.0C~99.9C, working humidity 0RH~99RH |

|

water immersion sensor |

RS-SJ-*-2 |

|

Contact water immersion sensor, monitors water accumulation in substations, cable trenches, control rooms and other places, working power supply: DC 10-30V, working temperature: -20C+60℃, working humidity: 0%RH~80%RH, response Time: 1s, relay output: normally open contact. |

|

camera |

CS-C5C-3B1WFR |

|

Supports 720P high-definition images, with the highest supported resolution up to 1.3 million pixels (1280*960). Built-in microphone and speaker have two-way voice intercom function. Supports EZVIZ Cloud Internet service, enabling remote interaction and video viewing through mobile phones, PCs and other terminals. |

|

smoke sensor |

BRJ-307 |

|

Photoelectric smoke sensor: Positive power supply (DC 12V): +12V Relay output: normally open contact |

|

access control |

MC-58(Normally open type) |

|

Normally open type, sensing distance: 30-50mm, material: zinc alloy, silver gray electric meter, dry contact output. |

|

Matching accessories |

ARTU-K16 |

|

Normally open type, sensing distance: 30-50mm Material: zinc alloy, silver gray electrical dry contact output |

|

KDYA-DG30-24K |

|

Output DC 24V; 24V power supply |

6.Conclusion

The application of the intelligent substation operation and maintenance management platform can transform the existing transmission and maintenance modes into remote online diagnosis of actual operating conditions and targeted inspections based on the health status of the equipment, greatly reducing the number of operation and maintenance personnel. Conduct operation, maintenance and inspection frequency of on-site relay protection devices to improve the level of refined management of equipment. The research on remote intelligent operation and maintenance technology of relay protection is of great significance.

references

[1] Acrel User Substation Comprehensive Automation and Operation and Maintenance Solution. Version 2020.05

[2] Enterprise Microgrid Design and Application Manual. Version 2020.06

[3] Wang Yan, Research on intelligent substation operation and maintenance technology [J]. Communications World, 2015 (22).

[4] Zhang Zhiqiang, Research on intelligent operation and maintenance management platform for substations.

Post time: Dec-26-2023